The Evolution of Smart Manufacturing Systems

In today’s rapidly evolving technological landscape, smart manufacturing systems are revolutionizing the way products are designed, produced, and delivered. These advanced systems leverage cutting-edge technologies such as artificial intelligence, the Internet of Things (IoT), and data analytics to optimize efficiency, reduce costs, and enhance competitiveness in the global market.

Smart manufacturing systems represent a paradigm shift from traditional manufacturing processes, which are often characterized by manual labor, inefficiencies, and limited flexibility. By integrating digital technologies into every aspect of the manufacturing process, companies can streamline operations, improve quality control, and respond more effectively to changing market demands.

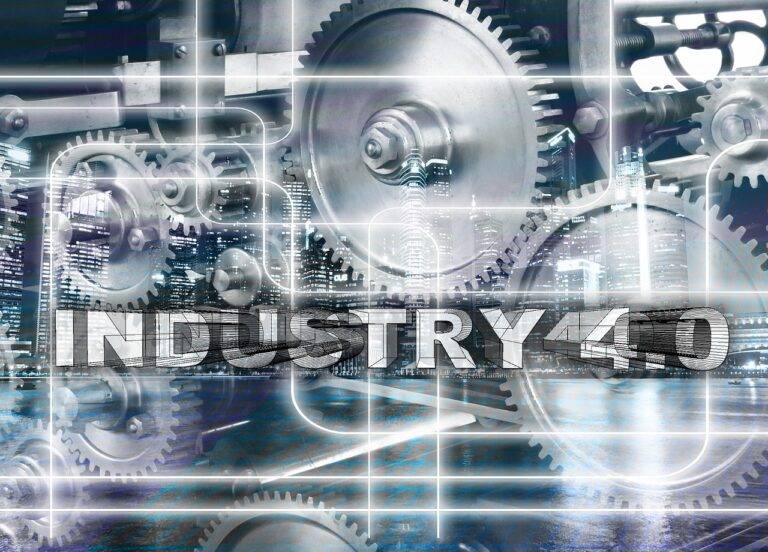

The Rise of Industry 4.0

The concept of smart manufacturing is closely linked to the fourth industrial revolution, often referred to as Industry 4.0. This new era of manufacturing is defined by the integration of cyber-physical systems, cloud computing, and advanced analytics to create “smart factories” that are highly interconnected and digitally driven.

Industry 4.0 technologies enable real-time monitoring and control of manufacturing processes, predictive maintenance of equipment, and seamless communication between machines and systems. By harnessing the power of data and connectivity, companies can achieve greater agility, responsiveness, and innovation in their operations.

Key Technologies Driving Innovation

Several key technologies are driving the evolution of smart manufacturing systems:

- Internet of Things (IoT): IoT devices such as sensors, actuators, and RFID tags enable real-time data collection and analysis, allowing manufacturers to monitor and optimize processes remotely.

- Artificial Intelligence (AI) and Machine Learning: AI algorithms analyze vast amounts of data to identify patterns, predict outcomes, and optimize production schedules, leading to improved efficiency and productivity.

- Big Data Analytics: Advanced analytics techniques are used to extract actionable insights from large datasets, enabling manufacturers to make data-driven decisions and continuously improve performance.

- Robotics and Automation: Robotics and automation technologies automate repetitive tasks, increase precision, and enhance safety in manufacturing environments, leading to higher throughput and lower labor costs.

- Additive Manufacturing (3D Printing): 3D printing technologies enable on-demand production of complex parts and components, reducing lead times and enabling mass customization.

Benefits of Smart Manufacturing

The adoption of smart manufacturing systems offers numerous benefits for manufacturers:

- Increased Efficiency: By optimizing processes and minimizing waste, smart manufacturing systems can significantly improve operational efficiency and resource utilization.

- Enhanced Quality Control: Real-time monitoring and analytics enable early detection of defects and deviations, ensuring higher product quality and reducing the risk of recalls.

- Greater Flexibility: Smart manufacturing systems are more agile and adaptable to changing market conditions, allowing companies to quickly reconfigure production lines and respond to customer demands.

- Cost Reduction: Automation of repetitive tasks, predictive maintenance of equipment, and energy-efficient operations help manufacturers reduce costs and improve profitability.

- Accelerated Innovation: By enabling rapid prototyping and iterative design processes, smart manufacturing systems foster innovation and enable faster time-to-market for new products.

Challenges and Considerations

Despite the numerous benefits of smart manufacturing, companies face several challenges in adopting and implementing these advanced systems:

- High Initial Investment: The upfront costs of implementing smart manufacturing technologies can be substantial, requiring significant capital investment and resources.

- Skills Gap: Companies may struggle to find and retain talent with the necessary skills and expertise to design, implement, and operate smart manufacturing systems.

- Data Security and Privacy: The proliferation of connected devices and data collection points raises concerns about data security, privacy, and the potential for cyberattacks.

- Interoperability and Standards: Ensuring compatibility and interoperability between different systems and technologies remains a challenge, requiring industry-wide standards and protocols.

FAQs

Q: What is smart manufacturing?

A: Smart manufacturing refers to the use of advanced technologies such as IoT, AI, and data analytics to optimize manufacturing processes, improve efficiency, and enhance competitiveness.

Q: What are the key technologies driving innovation in smart manufacturing?

A: Key technologies driving innovation in smart manufacturing include IoT, AI and machine learning, big data analytics, robotics and automation, and additive manufacturing (3D printing).

Smart manufacturing systems hold the promise of transforming the manufacturing industry, enabling companies to achieve greater efficiency, flexibility, and innovation in their operations. By embracing these technologies and overcoming implementation challenges, manufacturers can position themselves for success in the digital age.